How to Install a Griffin Radiator in the Early Z

This page details how to install a Griffin aluminum radiator into an early Datsun Z.

Background

My Z is Chevy V8 powered. I tried the rather large '79 ZX radiator, but it was

not quite efficient enough during the summer months (Note that the ZX radiator is

physically larger than the Griffin). I contacted Griffin radiator and explained my

situation. For my application they suggested a Nascar, 2 row, 1" tube, aluminum that

measures 24" wide and 19" tall. I then purchased the radiator, (P/N GRI-125202),

from Summit Racing, (1-800-230-3030), for $179.00.

After receiving the radiator, I measured everything and 3D modeled it with CAD.

I then measured my Z radiator core support and modeled it too. From these files, I

designed an attractive, lightweight, rigid, and adjustable mounting system. This system

required special tooling to fabricate and I would not expect the average mechanic to do

the same. However, the information supplied in this write-up should help get one started

and convey what to expect during the installation.

Basic Radiator Dimensions

The Griffin does not mount like a Z, or a Chevy. It does not use mounting

flanges, nor does it employ a designated supportive area on the tanks. It has C channel

rails, top & bottom. The C channel extends past the top and bottom of the tanks about

.2-.3". This is where the over all height (OAH) is measured and found to be

18.9". The tanks are actually 18.5" tall. The over all length (OAL) is measured

from outside edges of the tanks. This dimension is 24.0". The tanks are wider than

the core (2.25") and at the widest point (at the weld) are 3.1" wide. The water

inlet is 1.5" on the top left. The water outlet is 1.75" on the bottom right.

Note that the outlet has a slight angle towards the the Chevy water pump which takes a

little stress off of this fitting.

Fit Relative to Z Core Support

The Griffin fits, but not as well as one would like. When in the proper

position (gotta have about 1/2" between the hood and the cap), the lower channel will

be hanging down about 2" from the bottom of the lower core support rail. This is

measured at the lowest point of the support rail. Or, if measuring from the top of the

core support, 1/2" down to the top channel. Note that a radiator utilizing the the

slant corner filler will enable you to move the radiator up 1/2" to 1". I think

Ron Davis has one like this, but they are more expensive.

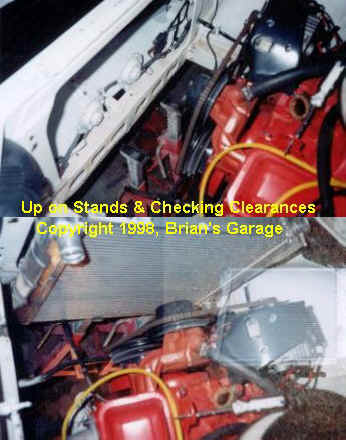

Use jack stands to position

the the radiator while checking clearances. This radiator will need to be about 1/2"

down from the top of the core support. To check clearance between hood and cap, place a

piece of modeling clay on the cap and slowly lower the hood. Before completely closing,

check to see how much the clay has compressed. You don't want to knock a high spot in your

hood. Use jack stands to position

the the radiator while checking clearances. This radiator will need to be about 1/2"

down from the top of the core support. To check clearance between hood and cap, place a

piece of modeling clay on the cap and slowly lower the hood. Before completely closing,

check to see how much the clay has compressed. You don't want to knock a high spot in your

hood. In this pic you will see that the tanks will be visible through the grill opening

as the radiator core is narrower than the opening in the core support. |

Building The Lower Mount

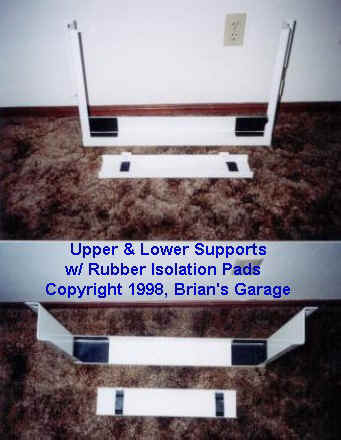

The lower mount should form a C Channel. The radiator tank edges will be

located fore and aft off of the C channel sides. The radiator will be suspended on it's

lower aluminum channel by the center (web) of the C channel.

Since the radiator hangs down below the core support rail, it would be a good

idea to make the front side (flange) of the channel at least 2.5" tall to protect

from sticks and stones. The other flange need only be about 1.5" tall.

The inside dimension between flanges should be a minimum of 3.38". The

maximum width of the tanks is 3.12", which leaves you with .25" for some rubber

material. You gotta have rubber in between all aluminum to steel contact points. It

doesn't take a genius to figure out why. I used .094" thick rubber. You can use

whatever is available, i.e. inner-tube rubber.

The channel should be 25" long. The distance between frame rails is about

26.5".

I made my

lower channel from 18 gauge and then welded this to a RH & LH 18 gauge Z section.

These Z sections had punched slots for up & down adjustment and bolted to the factory

radiator mounting holes. I made my

lower channel from 18 gauge and then welded this to a RH & LH 18 gauge Z section.

These Z sections had punched slots for up & down adjustment and bolted to the factory

radiator mounting holes.

|

Building The Upper Mount

The upper mount is also a C-channel. However, it does not locate the radiator

fore and aft using the sides of the tanks. The reason is that there really isn't much room

since one tank has a filler cap, and the other has an inlet in the way. Instead, locate

off the inside of the radiator upper channel.

I bent up an 18 gauge channel, 18.5" long. Flanges were 1.5" tall

with 3.38" measured inside between flanges.

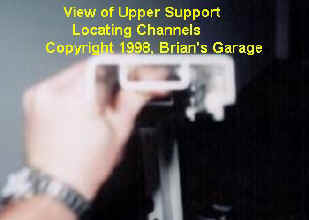

Next, I fabricated some more channel which fit

inside the radiator channel but left room for rubber isolation. These little channels were

welded to the inside of the larger piece. Next, I fabricated some more channel which fit

inside the radiator channel but left room for rubber isolation. These little channels were

welded to the inside of the larger piece. |

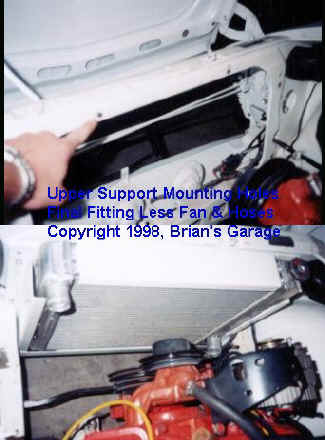

I drilled

two holes in the core support and matching holes in the upper mount. 1/4 NC nuts were then

welded to the inside of the upper mount. This allowed for a really clean look and also let

me retain my hood prop and factory paint code decal (cool!). I drilled

two holes in the core support and matching holes in the upper mount. 1/4 NC nuts were then

welded to the inside of the upper mount. This allowed for a really clean look and also let

me retain my hood prop and factory paint code decal (cool!). |

Finishing Up

At this stage we should have our mounts completed and installed, rubber

isolation at all contact points, and the radiator sitting pretty. Time to install the

tranny cooler, radiator hoses, and electric fan. I'm not going to talk about tranny cooler

and fan mounting (those are obvious), but I would like to give a few pointers on finding

the right radiator hoses.

To find the correct radius of hose, take a length of copper or aluminum tubing

and bend it to match the inside radius of the hose you will need. For example, I put one

side against the engine thermostat housing and then routed it to the inlet of the Griffin.

I tried to use a straight path while allowing for about a 6" radius before the inlet

to the Griffin. Do the same thing for the lower hose.

Now, go to your local "friendly" Napa store. Ask to see the hose

selection (it's normally hung on a wall in the back). Check the label to see what size

each end of the hose is (can be different). Lay your piece of tubing against the inside

radius until you find a match.

I ended up using a Gates/ECR

p/n 20608 for the lower hose and a Gates/ECR p/n 7368 for the top hose. I had to cut a

little off of each of these hoses. Note that the 20608 should work for a Chevy in the

"Set-Back" position also. I ended up using a Gates/ECR

p/n 20608 for the lower hose and a Gates/ECR p/n 7368 for the top hose. I had to cut a

little off of each of these hoses. Note that the 20608 should work for a Chevy in the

"Set-Back" position also. |

If you can't find a formed hose to fit, try a flex hose. The parts guys will

have a book listing hose lengths and diameters of each end of the flex hose. Flex hoses

generally wear out sooner and tend to restrict fluid flow.

Well, that's it. I hope this may have helped some of you.

|