|

|

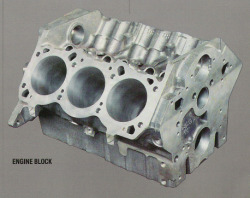

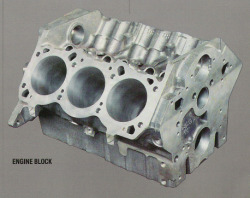

The 3300 engine block is designed to precisely align all components with the split-pin, even-fire crankshaft. When compared to the 3.0 MFI block, the left cylinder bank was moved 3.2 mm forward, while the right cylinder bank was moved 2.7 mm to the rear. This includes relocation of all lifter bores to maintain valve geometry. The corrosponding pushrod and rocker arm holes in the cylinder head are relocated accordingly. This change was incorporated to eliminate bore offset, which is present in many engines.

To reduce cylinder bore distortion, several design |

|

|

|

factors were implimented in the 3300 block. Improvements in the ribbing resist distortion, while the cylinder walls, and the cylinder deck are thicker than the 3.0 block.

Cylinder head gaskets on the 3300 are a Graphoil Laminate, which dispenses with the traditional steel flange. To use this type of flangless gasket, the cylinder head bolt torque is increased by 15%, and the cylinder head mating surfaces are ground to an overall flatness of .05 mm. The benifit is a 28% reduction in cylinder bore distortion. |

|