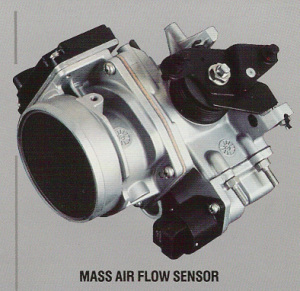

A heated wire is located in a bypass proportional air channel in the throttle body, and is heated to 75 degrees Centigrade (167 Degrees Farenheit) above inlet air temp. The amount of

Fuel Injector Assy

Fuel Rail Assy

Throttle Body Assy

The MAF sends updated air flow information to the ECM at a min. of once every 500 microseconds, or 2000 times per second, and increases with air flow. The information is used by the ECM in calculating the air/fuel ratio.

In addition, an oxygen sensor in the exhaust system is used to trim the ratio. The ECM performs an updated air flow calculation, and adjusts the fuel delivery every 3.125 ms. This means that regardless of ambient air temp, climatic conditions, altitude, or engine load, the air/fuel ratio delivered to the cylinders will always provide the optimum in combustion and fuel efficiency.

The Idle Air Control Valve (IAC) utilizes a 12mm dual slope pintle, as opposed to the 3.0's 10mm bypass channel and tapered pintle. This pintle profile contributes to good cold starts, and enhances idle characteristics at low ambient temps.