|

|

|||||||||||||||

|

|

|||||||||||||||

| Blending | |

|

Before grinding, the crushed beans are weighed and blended according to special recipes. The secret of every chocolate factory lies in the special mixing ratios. |

|

|

The finished product depends on the choice and the proportion of the various "grue" which enter into its composition. |

|

| Grinding | |

| The crushed cocoa beans, which are still fairly coarse are now pre-ground by special milling equipment and then fed on to rollers where they are ground into a fine paste. The heat generated by the resulting pressure and friction causes the cocoa butter (approximately 50% of the bean) contained in the beans to melt, producing a thick, liquid mixture. This is dark brown in colour with a characteristic, strong odour. | |

| During cooling it gradually sets: this is the cocoa paste. | |

| At this point the production process divides into two paths, but which soon join again. A part of the cocoa paste is taken to large presses, which extract the cocoa butter. The other part passes through various blending and refining processes, during which some of the cocoa butter is added to it. The two paths have rejoined. | |

| Cocoa Butter | |

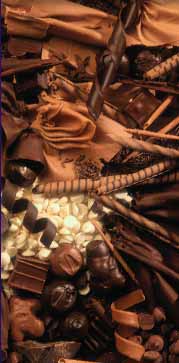

| The cocoa butter has important functions. It not only forms part of every recipe, but it also later gives the chocolate its fine structure, beautiful lustre and delicate, attractive glaze. | |

| < Page1 - 2 - 3 - 4 - 5 - 6 - 7 > | |

© 2004 The Chocolate Information Center. All rights

reserved.

This page was last modified on 22 September 2004.

This page was last modified on 22 September 2004.