Getting older, and having Multiple Sclerosis, the time has arrived to realize that I am starting to use a wheel-chair more often. I was using a cane, then using a walker for the last year in the residence and on very short trips, but that doesn't help when on longer trips. Using a wheel-chair helps prevent fatigue, and also the occasional fall. MS is a disability that is un-predictable and affects people in different ways. Fatigue and balance are the main changes in my abilities so far.

The pictures on here show the ramp we built here at my home. The ramp was built by my Brother, Brother-in-law, my youngest Son, my Son-in-law, and myself, although I could only do the design, and procurement of materials. Having MS, I am no longer able to do manual labor, only sit by, and keep track of what is happening.

Everyone worked well together, and all material needed was on site. Only problem we encountered was light rain the first day, but having an awning over the existing deck, allowed us to do a lot of the wood cutting there out of the rain.

The pictures are numbered in order, starting before construction on the ramp was started, and the last pictures taken after it was finished. Only thing left to do is put on stain and weather treatment. That will be done in Spring. All wood used is pressure treated, and used for outdoors.

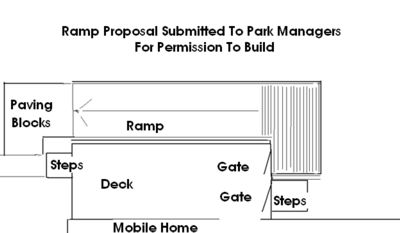

The first picture is a drawing I had to submit to the park managers, where we live, to get permission to build the ramp.

The following 5 pictures show the deck, where the ramp was built, before construction started.

#2

#2

#4

#4

On the 1st day, work was done by my brother Terry, brother-in-law Ron, my son Justin, and myself.

Pictures #6 and #7 show the 4x4 posts placed in holes where they will be located. The posts are 8 feet in length, holes are 2 feet deep, and when the ramp is built, the top of the posts will be cut, to a uniform height.

#7

#7Pictures #8 through #16 were taken at various times through-out the first day. A light rain fell most of the day, but we did most of the wood cutting on the deck under cover of the awning.

#9

#9

#11

#11

#13

#13

#15

#15

Work continued on the second day. Work was done by my brother Terry, brother-in-law Ron, my son-in-law Eric and myself. The weather was partly cloudy, with no rain all day. Work finished in mid-afternoon, leaving time for cleanup. A few minor things still needed to be done, and now thoughts would turn to the area at bottom of ramp leading to the sidewalk.

#18

#18

#20

#20

#22

#22

#24

#24

After the main work on the ramp was done, then thoughts turned to the bottom of the ramp, where it meets the sidewalk. After going to the local home center, my wife and I decided on paver bricks. It would take more work and time than pouring a concrete slab, but would be better we think in the winter.

The pavers are 8 inches by 4 inches, and the area covered required a little more than 150, but if we need to make the area bigger, or make some other changes, it will be easier than if there was a concrete slab.

#27

#27

#29

#29

#31

#31

#33

#33The next 3 pictures are of the turn area at the top of the ramp where it meets the deck. I have a gate there that can be closed when not using the ramp. When the gate is open, this allows about a 4 foot opening from the deck to a turn area, for access to the ramp. This turn area is 9 foot wide by 5 foot deep. More than enough to get wheelchair turned and aligned for ramp.

#35

#35

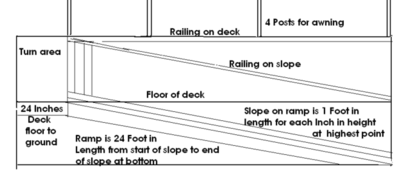

The next picture is a drawing I made of the ramp, looking at it from the side.

The next thing to do was to get rubber mats to extend from the top of the ramp to the bottom. This will make walking and traction better, and safer, than walking on the wood when it is wet.

The following 6 pictures were taken January 11, 2007. The day was sunny, and we still haven't had any snow, so I wanted to get some recent pictures.

The rubber mats were put on the ramp in mid-December. Each one is 1/8 inch thick, and 36x36 inches in size. They are made of rubber from re-cycled tires, and should last for a long time, depending on care. Time will tell.

Several pictures are of the brick area at the bottom of the ramp, as well as looking at the ramp from the sidewalk, near the street. The brick area will be updated in the Spring, with the bricks removed, the bedding for them re-done and compacted, then the bricks will be put back in and finish work done. It was done this time in a hurry, as we expected snow.

#38

#38

#40

#40

#42

#42Just a few items about the material used. We used all pressure treated wood, 2x8s under the flooring, 5/4x6s for the flooring, 4x4x8 for posts, 2x6s for handrails, 2x4s for inter-mediate handrail next to the deck, and lot's of screws. The distance between the handrails, and on the ramp for the wheelchair is 37 inches. My wheelchair is 26 inches wide at it's widest point. By making the access area 37 inches, I can use either the wheels on the chair or the handrails to move the wheelchair on the ramp.

I also moved the downspout from one side of the front steps, under the steps, to a point where the water would not be discharged on the pavers or sidewalk.

Total cost of the material used is about $1000, and we saved a lot by not having to hire a general contracter. Sure helps a lot to have relatives willing and able to help. My thanks go out to those who worked on this project, those mentioned above, and also to the wives who endure living with us.