| Training - SolidWorks® Advanced Part and Assembly Modeling.

Length: 24 Hours |

Lesson 1: Multibody Solids BridgingLocal Operations Combined Bodies Common Bodies Tool Body Symmetry Using Cut to Create Multibodies Saving Solid Bodies as Parts and Assemblies Feature Scope Splitting a Part into Multibodies Creating an Assembly Using Split Part with Legacy Data

Lesson 2: Weldments WeldmentsStructural Members Trimming Structural Members Adding Plates Weld Beads Using Symmetry Gussets and End Caps Profile Sketches Working with Weldments Managing the Cut List Custom Properties Weldment Drawings

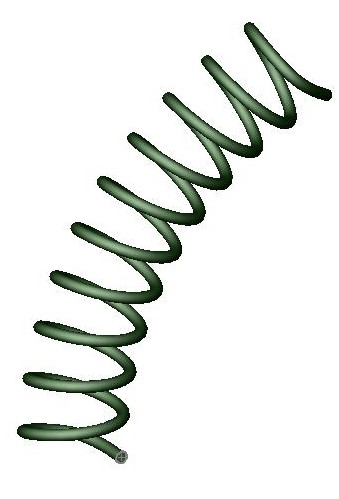

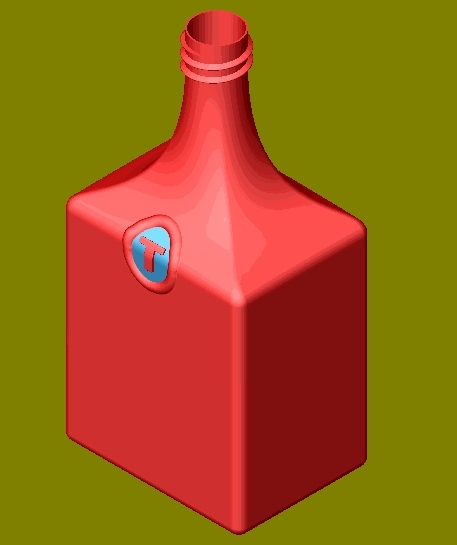

Lesson 3: Sweeps IntroductionCase Study: Bottle Sweeping and Lofting: What’s the Difference? Sweeping Creating a Curve Through a Set of Points The Label Shape Working with a Non-planar Path Variable Radius Filleting Analyzing Geometry Filleting the Label Outline Selecting Edges Performance Considerations Modeling Threads Sweeping Along Model Edges 3D Sketches

Lesson 4: Lofts Basic LoftingUsing Derived and Copied Sketches Copying a Sketch Derived Sketches Advanced Lofting Other Techniques

Lesson 5: Surfaces Working with SurfacesAdvanced Filleting Deleting Faces Dome Feature Offset Surfaces Extend Surface Hiding Bodies Intersection Curves and Splines Filling in Gaps Repairing Imported Surfaces

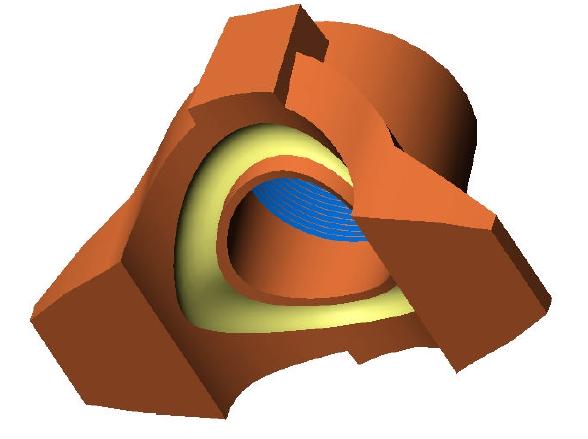

Lesson 6: Core and Cavity Mold Tooling DesignAnalyzing Draft on a Model Draft Analysis Colors Creating New Drafted Faces Scale to Allow for Shrinkage Determine the Parting Lines Shutting Off Holes or Windows Automation Modeling the Parting Surfaces Interlocking the Mold Tooling Creating the Mold Tooling Other Options for Tooling Design

Lesson 7: Top-Down Assembly Modeling Top-Down Assembly ModelingStages in the Process In-Context Features Building In-Context Parts Building Parts in an Assembly Assembly Patterning Propagating Changes Breaking External References Lesson 8: Working with Assemblies Working with AssembliesMating Shortcuts SmartMates Adding Mate References Feature Palette Parts Capture Mate References Inserting and Mating Components Configurations of Assemblies Assembly Design Tables Building the New Design Table Configuration Properties Changing Component Mates Lesson 9: Assembly Editing Assembly EditingEditing Activities Converting Parts and Assemblies Assembly Features Hole Series Replacing and Modifying Components Troubleshooting an Assembly Replacing Components Using Save As Controlling Dimensions in an Assembly Smart Fasteners Mirroring Components Lesson 10: Large Assemblies Large AssembliesEfficient Assemblies Errors When Opening an Assembly Designing with Sub-assemblies Modifying the Structure of an Assembly Large Assembly Mode Lightweight Components Taking Advantage of Configurations Drawing Considerations Using Component Patterns Advanced Selection Techniques Envelopes Layout Sketches in the Assembly SolidWorks Explorer Renaming Components |