|

Inkjet Dyes

Globally the importance of electronic print processes

is constantly gaining prominence. The growth of multi color inkjet

technology is especially growing in the home and office segments. A

substantial and thriving consumer market for inkjet can be noticed in

packaging, publication, and specialty areas.

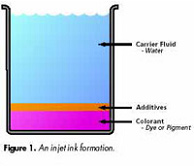

The quality of an inkjet printing is very much influenced by the

physico-chemical properties of printing ink. Here lies the importance of

inkjet dyes. Dyes for Inkjet ink are a bit different from the usual dyes

that are available for fibers. This is because of the fact that they

need to have high purity, and do contain small salt and inorganic

matters. Dye inks are prepared by dissolving of the liquid colored dyes

into a fluid carrier. This makes the dyes easy to apply. When it is

applied to a paper, the dyes are absorbed very uniformly so they reflect

light very evenly. As the printing is a high precision job the inkjet

dyes need to have superior quality in terms of colors, physical

properties, and stability. Generally direct, reactive, and acid dyes are

used as dyes for Inkjet Ink.

Inkjet dyes can also come in the form of powders

besides the usual liquids.

Given here is a few of the inkjet dyes that are available in the powder

form along with its characteristics.

| CI Name |

CI Number |

Concentration |

Quality |

Characteristics |

| Reactive Red 180 |

181055 |

100.00% |

Salt-free/RO |

Magenta (standard) |

| Acid Red 52 |

45100 |

400.00% |

Low salt |

Standard for toning as well as shading |

| Acid Blue 9 |

42090 |

165.00% |

Low salt |

Cyan (standard) |

| Direct Blue199 |

74190 |

175.00% |

Salt-free/ RO |

Greenish blue |

| Acid Yellow 23 |

19140 |

200.00% |

Salt-free/RO |

Red shaded Yellow (standard) |

| Direct Black 168 |

30410 |

165.00% |

Salt-free/RO |

Standard |

| Direct Black 19 |

35255 |

200.00% |

Salt-free/RO |

Standard |

Functioning of the Inkjet dyes

Functioning of the Inkjet dyes |

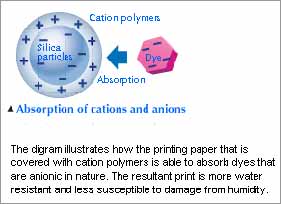

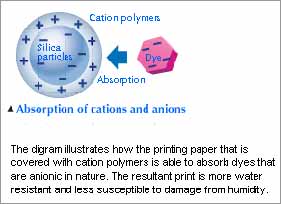

Inkjet print images,( with dye inks) uses a

particular method of fixing the dye firmly for making the prints durable

when they are stored.

Dyes that are generally used for inkjet printers is charged to anionic,

while cationic substances are used as a fixati for the dye.

Inkjet papers that has cationic polymers, have a superlative effect in

fixing the various dyes. As the following diagram illustrates.

Selecting

the right powder form Inkjet Dyes Selecting

the right powder form Inkjet Dyes |

- The powder form inkjet dyes should have a very low salt content.

- There must be the use of latest technologies like Reverse Osmosis

in the desalting process.

- Must possess a very fine particle size.

- The dyes must get easily soluble in water and other types of

co-solvents.

- Gives the right storage options.

- Must be Environment friendly.

- Last but not the least that gets easily converted into liquid "onsite"

Advantages

of Inkjet Dyes Advantages

of Inkjet Dyes |

Some of the major advantages of dyes used for inkjet

printers are listed below:

- Offers a wide gamut of colours.

- Bright intense colours.

- Wide selection.

- Stable and soluble.

Drawbacks

of Inkjet Dyes Drawbacks

of Inkjet Dyes |

A few of the drawbacks as experienced by the users of

the inkjet dyes in the printers is given below.

- There is a tendency for less stabilization.

- The print is not as much thick as of a pigment based ink.

- More damage prone to attacks of sunlight ozone and ultraviolet

rays.

Comparison

between Inkjet Dyes and Inkjet Pigments Comparison

between Inkjet Dyes and Inkjet Pigments |

There has been often a dilemma regarding the

colouring material of the ink whether to go for dye based inks or opt

for pigment based ones. Lets look at the pros and cons of both:

From the point of view of the manufacturers:-

| Dye

based Ink |

Pigment

Ink |

- As a result of sustained efforts over the years this

technology is now very well mastered in the industry. In fact

Dye based inks started long before the time that inkjet printers

even appeared on the market.

|

- The technology of pigment is comparatively difficult to

master as the problem of small size of the particles to create

in large quantities must be taken into account. As nano-sized

particles have to be manufactured that will be coated in a thin

resin.

This resin is used for protection

of the pigment against external chemical and mechanical attacks.

This has a problem too as it also helps in transportation of the

particle inside the ink, through the nozzles and finally onto the

paper. Thus it is quite clear that these contradictory constraints

make this technology a difficult proposition to perfectly master.

|

From the point of view of users:-

| Dye

Based Ink |

Pigment

Ink |

- The ink (dye based) is usually cheap though the manufacturing

cost is only one factor in ascertaining the selling price of

inkjet ink.

- Dye is usually fragile, when exposed to light and

Ultra-violet light, the colored molecules gets broken and loose

its color. This results in the prints to loose their original

colors and fades overtime.

- Ozone and several other common pollutants are also able to

chemically break down the color molecules.

- Drying time has a direct bearing with the drying time of the

solvent on the paper (often this leads to untimely closing of

nozzles, if the ink is set to dry very fast on paper).

Consequently, if the ink and its solvent is not quickly absorbed

by the paper, there is a risk of ink flow or paper deformation.

|

- The Pigment based inks solution gives longevity to. It is

thus no surprise that many printers are opting for such

pigments.

- Degradation of pigments by pollutants or ozone is not that

much, the presence of the resin coating limiting it further.

- Color density is generally better, or easier to achieve than

with dye-based inks.

- However talking of limitations pigments shows tendency to

promote a defect called bronzing. When brightly lit or if lit

with low incidence, the print can show unpleasant metal-like

reflections.

- Manufacturing costs are higher, therefore cost of the ink is

higher to the user.

|

|

|