| Ruwais Refinery Installations | ||||

|

CRUDE DISTILLATION AND DESALTING UNIT — 120,000 BPSD As a first step, prior to the actual distillation process, crude oil is passed through a desalter to remove the salts, water and sludge which are generally associated with any type of crude. It is then distilled to produce naphtha, kerosene, light gas oil, heavy gas oil and straight run residue, which are further processed in downstream units.

NAPHTHA HYDRODESULPHURISATION UNIT — 34,350 BPSD This unit processes the straight run full-range naphtha from the Crude Unit, and heavy naphtha from the Unibon Unit. It consists of two parts. The first is the reaction section, where the naphtha is desulphurised, and metals and nitrogen are removed. The second part of the unit is the fractionation section, where the reactor products are stripped to isolate gas and raw LPG streams. The raw LPG is sent to the GASCO-NGL plant for further processing. The naphtha is then split into light naphtha, which is used for gasoline blending, and heavy naphtha, which is the feedstock for the Catalytic Reformer Unit.

CATALYTIC REFORMER UNIT — 19,150 BPSD This unit process naphtha in order to improve its anti-knock properties by using a bimetallic platinum-based catalyst. Hydrogen-rich gas and 9S+ octane reformate are produced in addition to raw LPG which is routed to the GASCO-NGL plant for processing. The reformate is used as the main blend component for gasoline production, and the hydrogen-rich gas is used in the reaction sections of the hydrotreaters. The design of this conventional semi-regenerative unit is such that it can be converted into a continuous regenerative unit when required with minimum change and investment.

KEROSENE HYDROTREATER UNIT — 20,780 BPSD This unit is designed to improve the quality of straight run kerosene from the Crude Unit by using a nickel/tungsten catalyst. The process improves the burning quality of kerosene by desulphurisation and saturation of aromatics. This is required to meet international specifications for jet fuel.

HEAVY GAS OIL HYDRODESULPHURISER —21,850 BPSD This unit desulphurises the straight run heavy gas oil fraction prod in the Crude Distillation Unit by reaction under hydrogen using a cobalt/molybdenum oxide-based catalyst. The hydrotreated heavy gas oil is used as a blending component to produce different grades of gas ( VACUUM UNIT — 46,000 BPSD The Vacuum Unit is designed to process atmospheric residue from the the Ruwais Crude Distillation Unit plus a supplementary supply i Umm Al Nar Refinery. The unit produces light vacuum gas oil, h vacuum gas oil and vacuum residue. These are used respectively blending component for gas oil, as feed to the Unibon Unit, and blend stock for bunkers.

UNIBON UNIT (HYDROCRACKER)— 27,000 BPSD The Unibon Unit converts the heavy vacuum gas oil feed into lighter products in the reactor section by passing the feed, plus hydrogen, catalysts under high temperature and pressure. The products from reaction are then separated in the fractionation section to yield finished products ranging from LPG to gas oil. The hydrocracker catalyst was changed in 1989 to improve middle distillate yields and this has helped significantly to improve the Refinery's profitability.

HYDROGEN UNIT — 55 million SCF per day The Hydrogen Unit converts natural gas and steam to hydrogen with the aid of catalysts. Propane can be used either as an alternative feed or heating source. In the hydrogen purification section, the Union Carbide Pressure Swing Adsorption Process (PSA) is used. The unit is capable of producing S3 million standard cubic feet (scf) per day of hydrogen.

TWO SOUR WATER STRIPPING UNITS — 2,470 BPSD and 3,925 BPSD The purpose of these units is to improve the quality of water effluent from the Refinery, reducing pollution by removing the major part of hydrogen sulphide and ammonia dissolved in the sour water from the process units by steam stripping. The stripped water is reused as part of the Crude Unit desalter feed water. This reduces the demineralised water make-up to the desalter.

TWO ACID GAS REMOVAL UNITS — 9,990 NM3/hr and 9,520 NM3/hr These units help to minimise pollution by improving the quality of fuel gas produced in the Refinery. They sweeten the sour fuel gas produced from the various process units by absorbing the hydrogen sulphide gas in diethanolamine (DBA) solution. Sweet fuel gas is then sent to the Refinery fuel gas system. The hydrogen sulphide-rich solution of DEA is regenerated by steam heating. The stripped hydrogen sulphide is fed to the downstream Sulphur Recovery Units.

TWO SULPHUR RECOVERY UNITS — 44/49 tonnes per day These units recover sulphur from hydrogen sulphide-rich gas received from the upstream Acid Gas Removal Units, by converting it into elemental sulphur through a thermal and catalytic reaction. The liquid sulphur is then sent to the Sulphur Handling Terminal for granulation and export.

The Refinery generates all the utilities which are required by the process units. Equipment and systems include desalinators, steam boilers, a sea water cooling system, a closed-loop fresh water cooling system, fuel oil and fuel gas systems.

TANK FARM AND OFFSITES Working storage capacities of feed and main products it the Refinery are as follows (cubic metres): • Crude oil 161,700 • Butane and propane 2,600 • Export naphtha 98,800 • Reformate 47,200 • Super gasoline 90 42,800 • Special gasoline 97 82,700 • Aviation turbine kerosene 161,000 • Gas oil 261,300 • Bunker 'C' 154,600 • Fuel oil 65,700 Offsites include ballast reception and treatment facilities, API separator system, two flares with standard facilities, TEL reception, storage and blending facilities, and limited truck loading facilities for various products.

MARINE TERMINAL The Refinery's Marine Terminal provides for the loading and unloading of tankers ranging from 2,000 to 100,000 dwt. It has eight cabotage berths to accommodate tankers from 2,000 to 7,000 dwt, one large tanker berth for vessels of between 7,000 and 80,000 dwt, and another large tanker berth for vessels between 20,000 and 100,000 dwt.

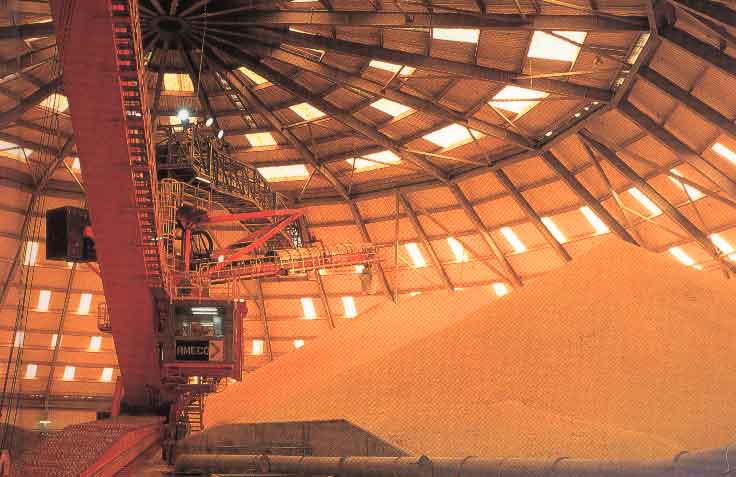

SULPHUR HANDLING TERMINAL The Ruwais Sulphur Handling terminal was built to receive liquid sulphur from the two ADNOC refineries, Habshan and Das Island and to granulate it for export. Liquid sulphur from Das Island is shipped to Ruwais via a dedicated sulphur vessel of 9,000 tons dwt, while a fleet of 30-ton road tankers transport supplies from elsewhere. The liquid sulphur is stored in Four insulated, steam-heated tank with a total capacity of 40,000 tons. These tanks can feed the nine granulation units of a total processing capacity of 5,000 tons per day (with provision for future expansion). Granulated sulphur for export is then stockpiled in a sulphur storage unit capable of holding up to 40,000 tons.(Circular Storage Unit) and 110,000 tons(Linear Storage Unit). The Sulphur Handling Terminal has its own jetty for loading vessels of up to 25,000 tons, as well as receiving shipments of liquid sulphur from ADGAS.

GENERAL UTILITY PLANT A successful industry requires dependable and adequate power and water supplies. The Ruwais Industrial Complex is no exception, and a central services plant supplies electricity, distilled water, potable water, sea water and back-up fire water to the various installations within the complex. Commissioned in 1983, the General Utility Plant has the following facilities: • Twenty Four sea water supply pumps, with a total capacity of 115,000 cubic metres an hour to cater for the sea water needs of the EDC, Refinery, the Fertil plant and the General Utilities Plant. • Five steam generating units each with a capacity of 250 tons per hour. • Three 18 MW GE gas generators. Four ABB Gas Turbines each 140 MW • Two 45 MW steam turbo generators. • Five desalination units, each capable of providing 27,000 cubic metres per day of distillate water. Six Instrument Air Compressors Water Treatment Plant Demi Water Plant

QUALITY CONTROL All feed streams and finished products from the Ruwais process units, General Utilities Plant, and Sulphur Handling Terminal are analysed in the Refinery laboratory, which certifies them to meet international specifications. In addition, all products sold from the Refinery are certified by an independent third-party quality surveyor. This attention to quality control ensures that Takreer maintains its reputation as a supplier of top-class products to the world market.

|

Refinery Utilities

|

|||

| Refinery Utilities

|

||||

|

|

||||